Views: 20 Author: Site Editor Publish Time: 2025-10-28 Origin: Site

A diesel generator is a power device that converts the chemical energy of diesel into electrical energy.It is widely used in scenarios such as backup power,self-provided power,peak-load power,and mobile power.Its working principle can be divided into four main stages:intake,compression,combustion,and exhaust.Here is a detailed description of each stage:

(1)Intake Stage

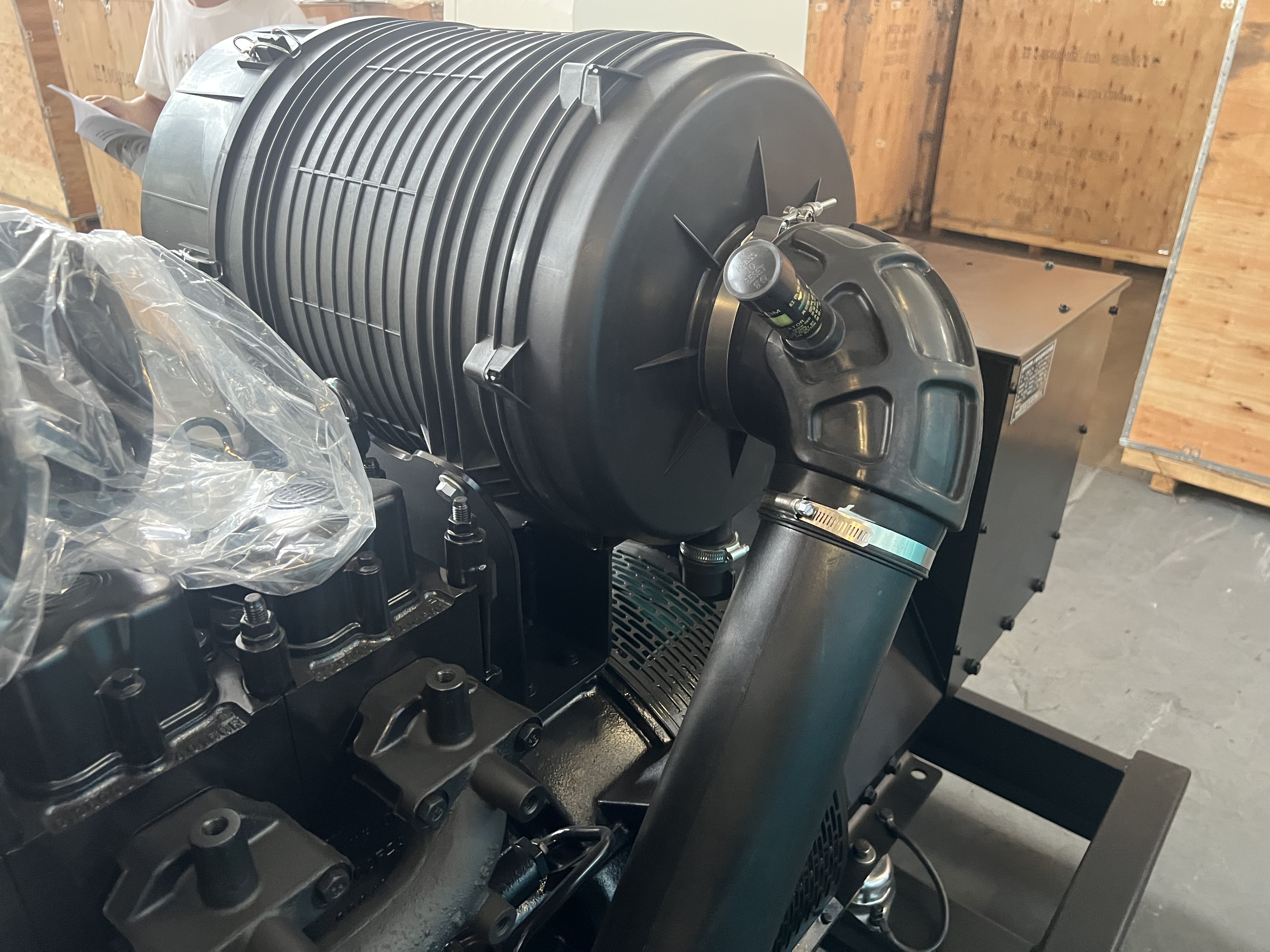

During the intake stage,the piston moves from the top dead center to the bottom dead center,reducing the pressure inside the cylinder and creating a vacuum.Air enters the cylinder through the air filter.The air filter's role is to filter out dust and impurities from the air,ensuring that the air entering the cylinder is clean,thereby improving combustion efficiency and reducing engine wear.

• Importance of Air Filter:The air filter not only filters dust but also prevents foreign objects from entering the cylinder,avoiding damage to components such as the piston and cylinder wall.Regularly replacing the air filter is key to maintaining engine performance.

• Intake System Design:The design of the intake system is crucial for engine performance.An efficient intake system can reduce intake resistance,increase air intake,and thus boost engine power and efficiency.Modern diesel engines often employ turbocharging technology,which uses the energy of exhaust gases to increase intake pressure,further enhancing air intake and combustion efficiency.

(2)Compression Stage

After the piston reaches the bottom dead center,it begins to move upward to the top dead center,compressing the air inside the cylinder to a high-pressure state.At this point,the temperature and pressure of the air inside the cylinder rise sharply,creating conditions for the combustion process that follows.

• Effect of Compression Ratio:Diesel engines typically have a high compression ratio(14:1 to 25:1),which significantly increases the temperature and pressure of the air after compression,providing the necessary conditions for the self-ignition of fuel.A high compression ratio not only improves combustion efficiency but also reduces fuel consumption and pollutant emissions.

• Formation of High-Temperature and High-Pressure:During the compression process,the temperature of the air inside the cylinder can reach 500°C to 700°C,and the pressure can reach 3MPa to 5MPa.This high-temperature and high-pressure environment enables the fuel to self-ignite rapidly,releasing a large amount of heat energy.

(3)Combustion Stage

When the piston is near the top of the cylinder,the fuel injector sprays high-pressure fuel into the cylinder in a misty form.The fuel mixes with the high-temperature,high-pressure air and self-ignites,producing a large amount of heat energy.The heat energy released by this combustion process pushes the piston downward,thereby rotating the crankshaft.

• Fuel Injection System:Modern diesel engines typically use high-pressure common-rail technology,which can precisely control the timing and quantity of fuel injection,improving combustion efficiency and reducing pollutant emissions.The high-pressure common-rail system pressurizes the fuel to a high-pressure state through a high-pressure fuel pump and then sprays the fuel into the cylinder in a misty form through the fuel injector.

• Self-Ignition Point:Diesel has a relatively low self-ignition point,usually between 250°C and 350°C,which allows diesel to self-ignite rapidly in the high-temperature,high-pressure cylinder.The self-ignition point directly affects fuel combustion efficiency and engine performance.

• Combustion Process Control:The control of the combustion process is very important.It is necessary to precisely control the timing and quantity of fuel injection to ensure complete and efficient combustion.Modern diesel engines are usually equipped with an electronic control unit(ECU),which monitors and regulates the combustion process in real-time through sensors and controllers.The ECU can automatically adjust fuel injection parameters according to the engine's operating status and load requirements,optimizing the combustion process and improving engine performance and efficiency.

(4)Exhaust Stage

The exhaust gases produced after combustion are expelled from the cylinder through the exhaust valve.At the same time,the intake valve opens,allowing new air to enter the cylinder in preparation for the next cycle.

• Exhaust Gas Treatment:To reduce environmental pollution,modern diesel generators are usually equipped with exhaust gas treatment systems,such as catalytic converters and particulate filters,to reduce the emissions of nitrogen oxides and particulate matter.Catalytic converters chemically convert nitrogen oxides into nitrogen and water,while particulate filters physically filter out particulate matter.

• Turbocharger:Many diesel engines are also equipped with turbochargers,which use the energy of exhaust gases to increase intake pressure,thereby increasing engine power and efficiency.Turbochargers not only increase air intake but also reduce fuel consumption and pollutant emissions,making them a very effective energy-saving and environmentally friendly technology.

(5)Control System

The control system of a diesel generator is responsible for monitoring and regulating the engine's operating status to ensure stable and efficient operation under various conditions.

• Automatic Start-Up and Shutdown:The control system can automatically detect the power supply status of the grid.It starts the generator automatically when the grid power is interrupted and shuts it down automatically when the grid power is restored.The automatic start-up and shutdown functions are realized through voltage and current sensors,ensuring the continuity and reliability of power supply.

• Voltage and Frequency Regulation:The control system regulates the engine's speed and the generator's excitation current to ensure stable output voltage and frequency of the generator.Voltage and frequency regulators monitor and regulate the engine's operating status in real-time through sensors and controllers,improving the generator's performance and reliability.

• Protection Functions:The control system also has various protection functions,such as overload protection,short-circuit protection,low oil pressure protection,and high-temperature protection,to prevent the generator from being damaged under abnormal conditions.These protection functions are realized through sensors and controllers,ensuring the safe operation of the generator.

Summary

Although the working principle of diesel generators is complex,it can achieve efficient and reliable power supply through rational design and advanced technology.Understanding its working principle helps to better maintain and use diesel generators,ensuring that they can provide stable power support when needed.Regular maintenance and upkeep are crucial for maintaining the performance of diesel generators and extending their service life.